3D Printing and Machining - Technical Ceramics

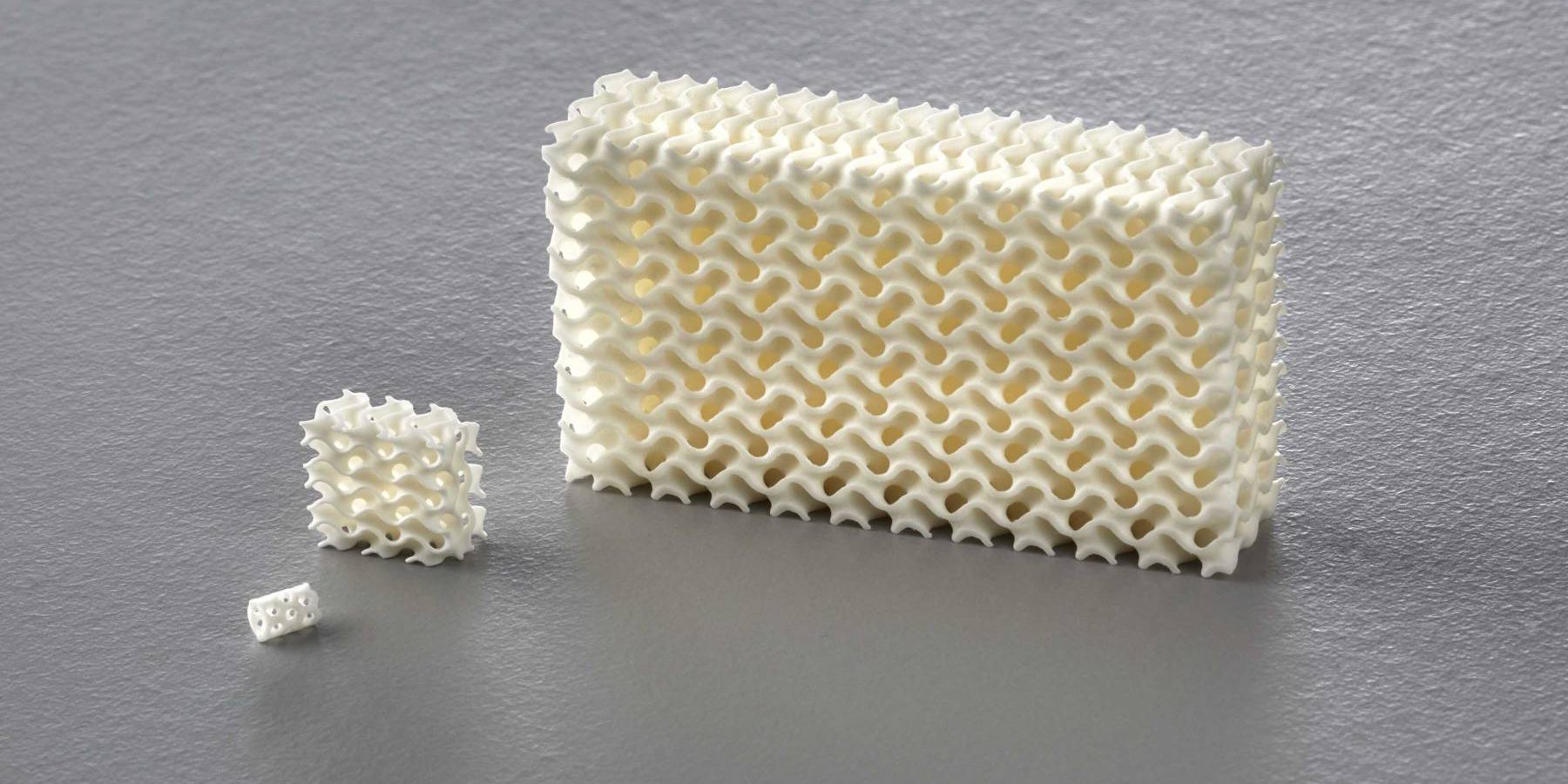

HIGH-PRECISION COMPONENTS MADE OF 3D-PRINTED CERAMICS

Ceramic 3D printing enables high-precision measurements under extreme conditions

Complex analysis crucible for gravimetry

Our innovative, 3D-printed ceramic crucible enables high-precision thermogravimetric measurements with an accuracy of up to 1µg, even at extremely high temperatures and pressures.

Functionalized surfaces thanks to 3D-printed ceramic nozzle

New possibilities for plasma treatment

A new type of ceramic nozzle combines plasma with FDM printing. The plasma treatment of individual layers in the printing process enables defined adhesive properties, the sterilization of surfaces and the creation of conductive layers.

Ceramic 3D printing contributes to

Development of clean nuclear energy

Hilgenberg Ceramics supports EU project MYRRHA

3D-printed ceramics support European researchers in the design of an innovative nuclear reactor. This EU project aims to make super-GAUs impossible, drastically reduce nuclear waste radioactivity and produce isotopes for cancer research.

Additive manufacturing, or simply 3D printing, has undergone enormous development in all areas in recent years. Due to expiring patents, the first functioning business models and increased public interest, an innovation process has been set in motion. Innovation is taking place in all areas, from materials to machines, software and even marketplaces.

A new sector of the economy emerged with growing importance every day.

In the past, this development has primarily been limited to metals and plastics. Ceramics have only had a niche existence in the 3D printing sector and have so far mainly been used in the academic field.

The reasons for this were the difficulty in mastering the technology and the resulting high costs. This meant that there were hardly any providers worldwide.

The majority of the costs do not lie in ceramic 3D printing itself. Rather, the entire value chain must be considered: CAD design, preparation of the CAD data, cleaning of the finished parts, debinding and sintering are all more complex and therefore more cost-intensive than 3D printing itself.

We at Hilgenberg-Ceramics have made this challenge our core competence.

Lean structures, everything under one roof, design, 3D printing, post-processing, debinding and sintering ensure fast processing and efficient pricing, especially when it goes beyond prototyping.

With our innovative pricing tool, you can estimate the costs for the component quickly and easily by uploading your STL data. Just give it a try.