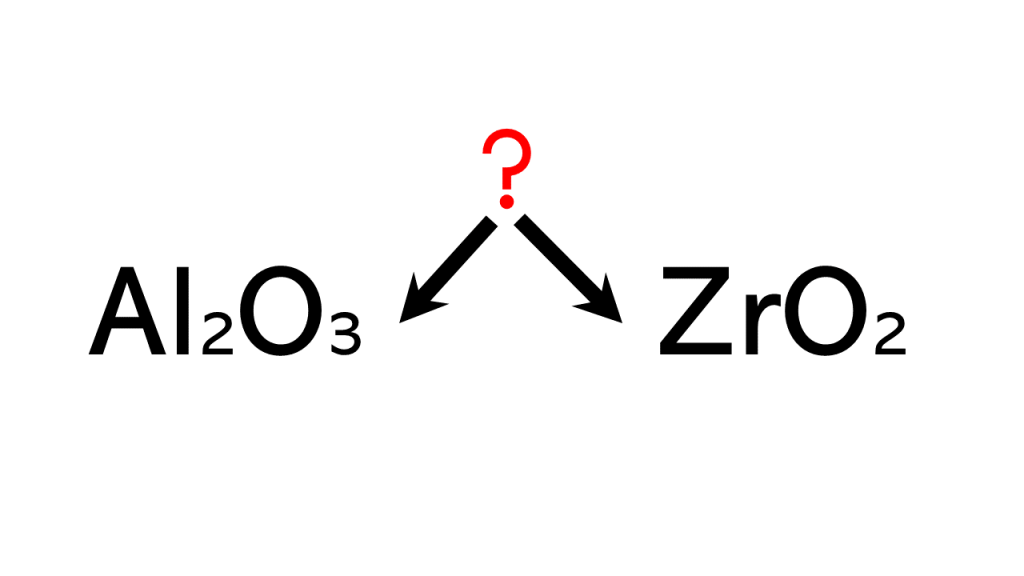

We offer the following 3D printing materials Al2O3 and ZrO2 on. Depending on the application, the right choice of material is crucial. However, the geometry of the component can also influence the choice of material, as Al2O3 and ZrO2 differ in their manufacturing parameters and therefore in their technical possibilities. It is therefore always advisable to consider each individual case.

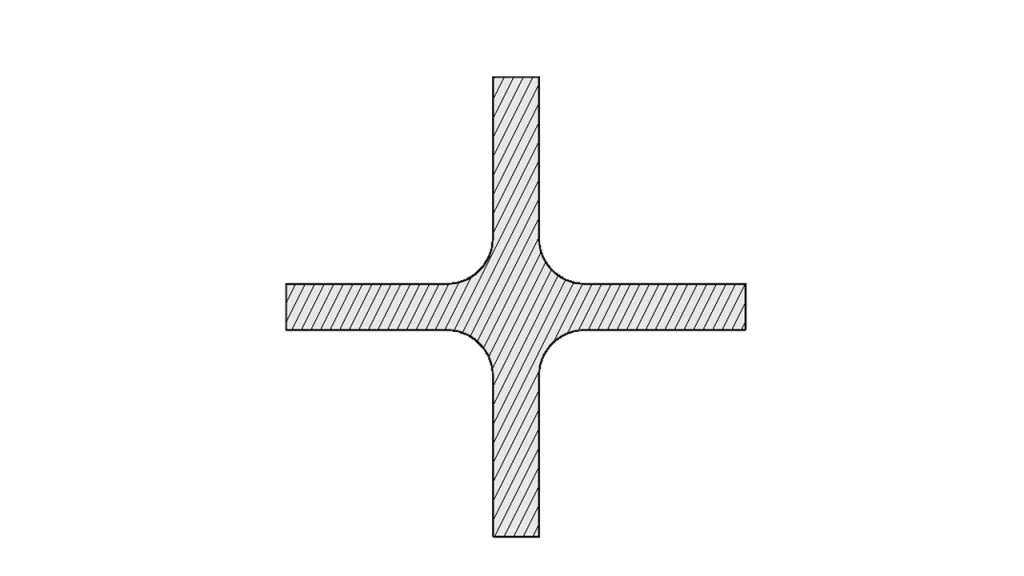

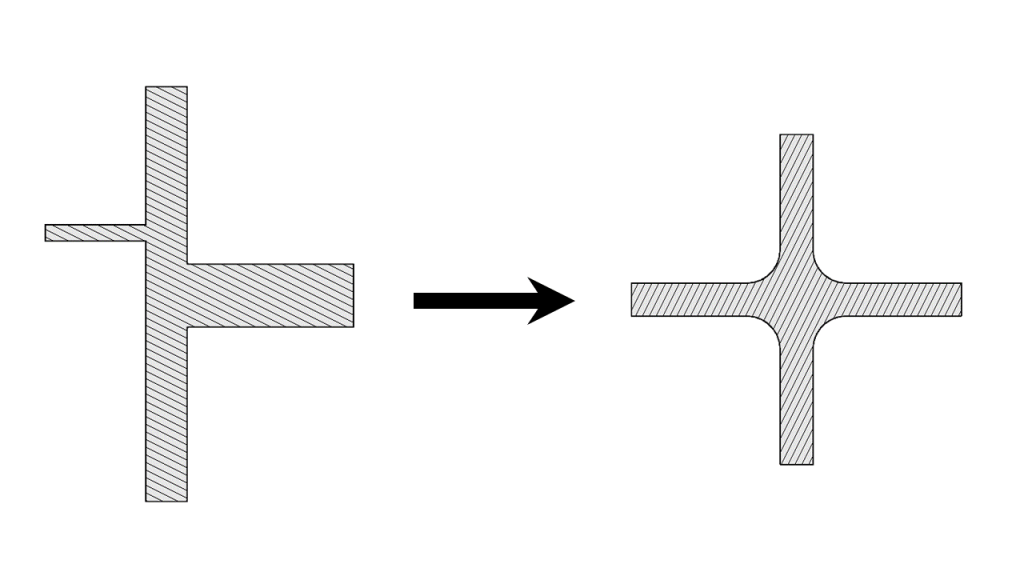

We are happy to design the component to be printed for you based on your specifications, drawings or sketches. In doing so, we take into account the technical limits of 3D printing and the characteristics of the ceramic-compatible design.

For machine components that were originally designed for steel in accordance with ISO 2768, a 1:1 transfer to ceramic is not possible in most cases. Shaping using 3D printing must also be taken into account.

We will be happy to adapt the design of your component accordingly.

We have the know-how of the entire value chain. In contrast to the 3D printing of plastics or metals, the actual 3D printing of ceramics is only one part of the manufacturing process, which can only be completed by debinding and sintering. Thanks to the in-house production of the total work flows we act cost-efficiently, individually and quickly.

© 2025 Hilgenberg-Ceramics GmbH & Co. KG